EGO — Press Release on Platform Screen Door Systems

Official announcement describing the initiative to install platform-screen doors to separate platforms from tracks.

A Platform Screen Door (PSD) is an automated glass door system installed along the platform edge of metro and train stations that opens in perfect sync when the train arrives. By preventing passengers from falling onto the tracks, it averts serious accidents. It also regulates airflow, temperature, and noise within the station, providing a more comfortable and secure travel experience. Widely adopted in modern urban transit networks, PSD systems elevate safety, energy efficiency, and hygiene standards in public transportation.

Learn more about Platform Screen Door (PSD) systems—an indispensable component of modern transit that enhances passenger safety in metro and rail stations.

PSD systems open and close automatically in perfect synchronization with train movements, ensuring maximum safety.

With a modern appearance that seamlessly integrates with station design, platform doors enhance your brand image.

Platform separator door systems, also known as Platform Screen Doors (PSDs) or Platform Edge Doors (PEDs), represent one of the most significant safety innovations in modern public transportation infrastructure. These sophisticated barrier systems create a protective glass or metal wall between waiting passengers and active railway tracks, fundamentally transforming the safety landscape of subway stations, metro systems, and rapid transit networks globally.

The primary function of these systems extends beyond simple passenger protection, encompassing comprehensive safety management, climate control, energy efficiency, and operational optimization. Modern platform separator doors integrate advanced sensors, automated control systems, and fail-safe mechanisms that ensure seamless coordination between train arrivals and door operations, creating a safer and more controlled environment for millions of daily commuters worldwide.

The implementation of platform separator door systems has demonstrated remarkable success in preventing track-related accidents, with studies showing up to 89% reduction in fatal incidents. These systems effectively eliminate risks associated with accidental falls, intentional harm, and overcrowding-related accidents that have historically plagued busy transit stations.

Beyond preventing tragic accidents, platform separator doors significantly reduce the psychological stress experienced by commuters in crowded stations, particularly during peak hours. The physical barrier provides peace of mind for passengers with mobility challenges, parents with young children, and individuals who may experience anxiety in crowded underground environments.

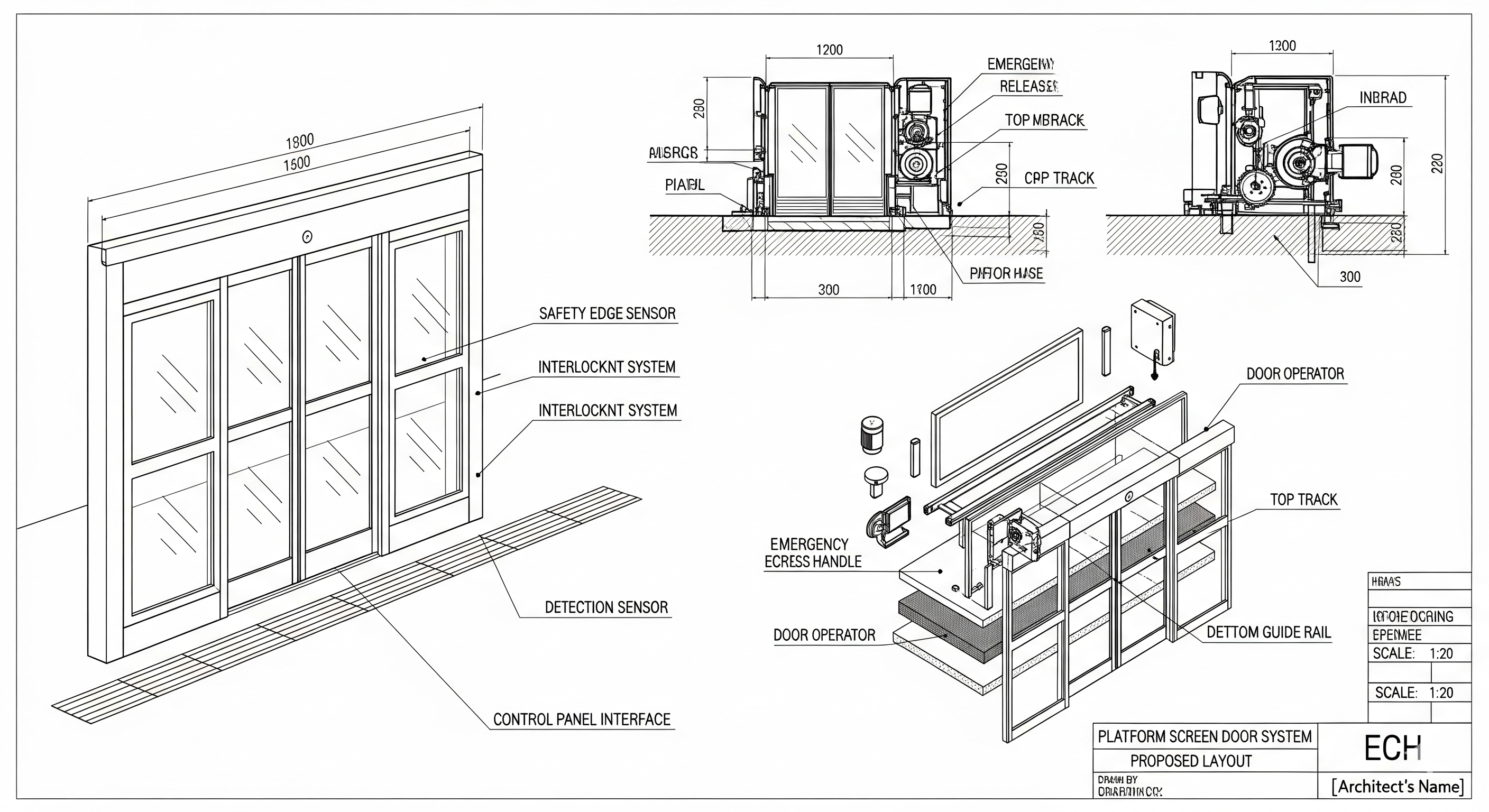

Modern platform separator door systems incorporate sophisticated engineering solutions that must meet stringent international safety standards and regulatory requirements. Full-height systems typically extend from platform floor to ceiling, measuring approximately 2.1 to 3.0 meters in height, while half-height alternatives range from 1.2 to 1.5 meters, providing adequate protection while maintaining visual continuity.

The door panels themselves are constructed from tempered safety glass or reinforced polycarbonate materials, designed to withstand significant impact forces while maintaining transparency for security monitoring. Advanced motor systems, typically utilizing servo-driven mechanisms, ensure precise synchronization with train door operations, accommodating various rolling stock configurations and door spacing requirements.

The financial investment required for platform separator door installation varies significantly based on station complexity, system specifications, and local infrastructure requirements. Current industry estimates indicate costs ranging from $1-5 million per station, with full-height systems commanding premium pricing compared to half-height alternatives.

However, comprehensive cost-benefit analyses demonstrate substantial long-term economic advantages, including reduced insurance liabilities, decreased emergency response costs, improved operational efficiency, and enhanced ridership confidence. Many transit authorities report that initial installation investments are offset by operational savings and increased revenue within 5-7 years of implementation.

Platform separator door systems are broadly categorized into two primary configurations: full-height and half-height systems, each designed to address specific operational requirements and safety objectives. Full-height systems provide complete physical separation between platform and track areas, extending from floor to ceiling and offering maximum safety protection along with climate control benefits.

Half-height systems, measuring approximately chest-high, offer a cost-effective compromise between safety enhancement and visual openness. These systems are particularly popular in outdoor or elevated stations where complete enclosure is unnecessary, while still providing adequate protection against accidental track access and maintaining emergency evacuation capabilities.

The installation of platform separator door systems requires meticulous planning, coordination with ongoing transit operations, and adherence to strict safety protocols to minimize service disruptions. Typical installation projects span 6-18 months, depending on station complexity, system specifications, and the need to maintain regular service during construction.

Pre-installation phases include comprehensive site surveys, structural assessments, utility relocations, and detailed coordination with rolling stock manufacturers to ensure perfect door alignment. The construction process involves platform modifications, electrical system integration, control system installation, and extensive testing phases to verify all safety and operational requirements are met.

Effective maintenance of platform separator door systems requires specialized technical expertise, regular inspection schedules, and proactive component replacement programs to ensure optimal performance and safety compliance. Daily operational checks include door alignment verification, sensor calibration, emergency override system testing, and general cleanliness maintenance.

Comprehensive preventive maintenance programs typically include monthly mechanical inspections, quarterly electrical system evaluations, semi-annual safety system certifications, and annual structural integrity assessments. Advanced predictive maintenance technologies, including IoT sensors and remote monitoring systems, enable real-time performance tracking and early identification of potential issues before they impact service reliability.

Cities across the globe have demonstrated remarkable success with platform separator door implementation, providing valuable insights for future projects and system optimization strategies. Asian metropolitan areas, including Hong Kong, Singapore, and Seoul, have achieved near-universal platform door coverage, resulting in dramatic safety improvements and enhanced passenger confidence.

European implementations in cities like Copenhagen, Vienna, and Paris have focused on retrofitting existing infrastructure while maintaining architectural heritage and operational continuity. North American projects, including recent installations in New York City and planned implementations across various transit systems, demonstrate growing recognition of platform door benefits despite higher retrofit costs and complex regulatory environments.

The future of platform separator door technology lies in intelligent systems that integrate seamlessly with broader smart city infrastructure, autonomous train operations, and predictive analytics platforms. Advanced sensor technologies, including LIDAR, thermal imaging, and AI-powered crowd monitoring systems, will enable more sophisticated safety management and operational optimization.

Emerging innovations include modular installation systems that reduce construction time and costs, energy-harvesting door mechanisms that generate power from passenger movement, and adaptive door configurations that can accommodate various train types automatically. Integration with mobile applications and digital signage systems will provide passengers with real-time information and enhanced wayfinding capabilities.

Platform screen door systems are safety barriers installed between passengers and the tracks at metro and rail system stations. These systems protect passengers waiting on the platform from the risk of falling onto the tracks when a train approaches and significantly enhance station safety.

Establishes a safe waiting area by creating a physical barrier between the passenger and the train.

Ensures safe boarding and disembarking by opening in perfect sync with train doors.

Helps prevent accidents such as falls onto the tracks and pushing incidents, enhancing passenger safety.

Platform Screen Door systems prevent passengers from falling onto the tracks, minimizing accidents.

The enclosed system maintains in-station climate control, delivering energy savings.

PSD systems that open simultaneously with train doors enable fast and safe boarding and alighting.

Compared with open platforms, it controls dust, noise, and drafts, creating a more comfortable environment.

For detailed information about PSD Contact

PSD is an automatic door system placed between passengers and rails in subway and train stations. It increases safety and prevents accidents.

When the train arrives at the station, the PSD doors open in synchronization with the train doors and boarding and alighting takes place safely.

In addition to safety, it provides energy savings, climate control, noise reduction and hygiene levels in stations.

It is actively used in some modern metro lines in big cities such as Istanbul and Ankara and is becoming widespread.

Official announcement describing the initiative to install platform-screen doors to separate platforms from tracks.

Technical and historical background on PSD systems and their use in urban transit.

Sector analysis and case studies covering design, safety and performance metrics.